Driven by the continual pursuit of technological innovation, SHANGHAI TALENCO recently achieved a successful convert of the traditional two-component pneumatic sprayer GP2440. Based on its original spraying function with grouting capabilities, offering customers a wider application choices and more efficient construction solutions.

GP2440 is already widely used in industries such as construction and automotive for its ability to operate two spray guns, enabling rapid application of different coatings. However, for scenarios requiring filling, sealing, or reinforcement tasks, the singular spraying function proved somewhat limiting.

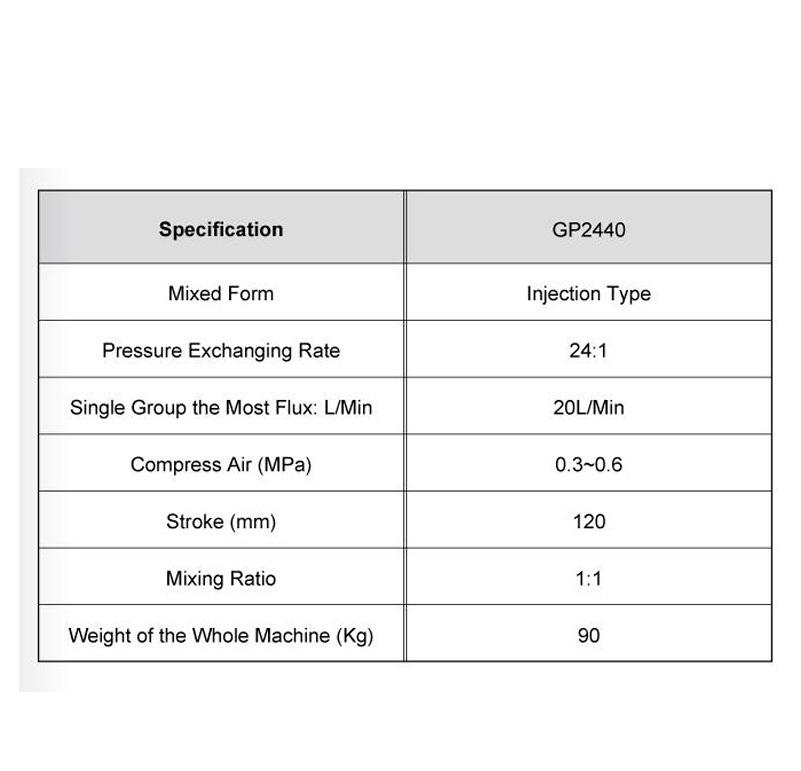

Before: GP2440

GP2440 Spec.

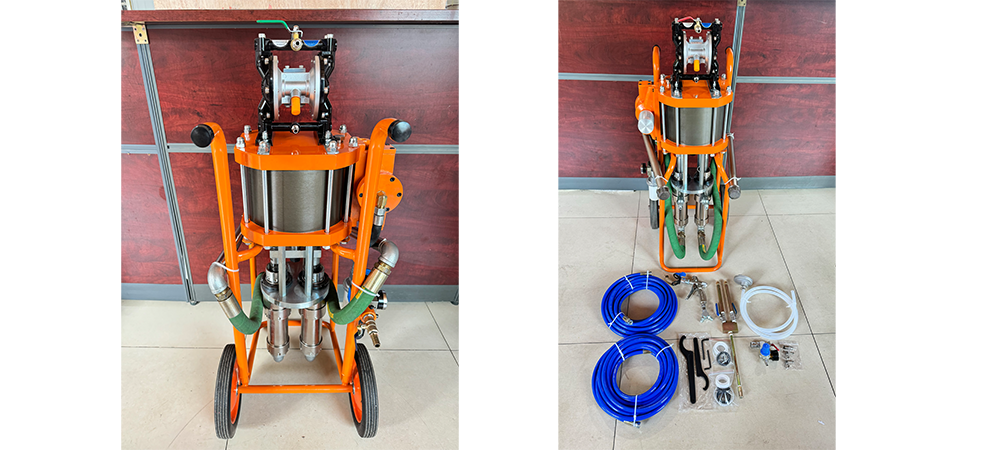

To address this, by adding an injection gun and a diaphragm pump, GP2440 was converted into a grouting machine. The introduction of injection guns enabled the spray machine to undertake grouting tasks, thereby expanding its application scope to cover more sectors such as construction and underground engineering, providing a fresh solution for tasks like filling, sealing, and reinforcement.

Moreover, the addition of diaphragm pumps not only endowed the spray machine with self-cleaning functionality to ensure long-term stable operation but also enhanced equipment reliability and durability, reducing maintenance and cleaning time costs, thus saving customers valuable time and resources.

This innovative represents a technological breakthrough, offering customers a more comprehensive and efficient construction solution. It enables the same equipment to meet traditional spraying demands while also being capable of handling more complex tasks like grouting, further elevating customers’ construction efficiency and work quality.

To learn more about GP2440 two-component sprayer.

After: GP2440 with an injection gun and a diaphragm pump

WhatsApp us

WhatsApp us